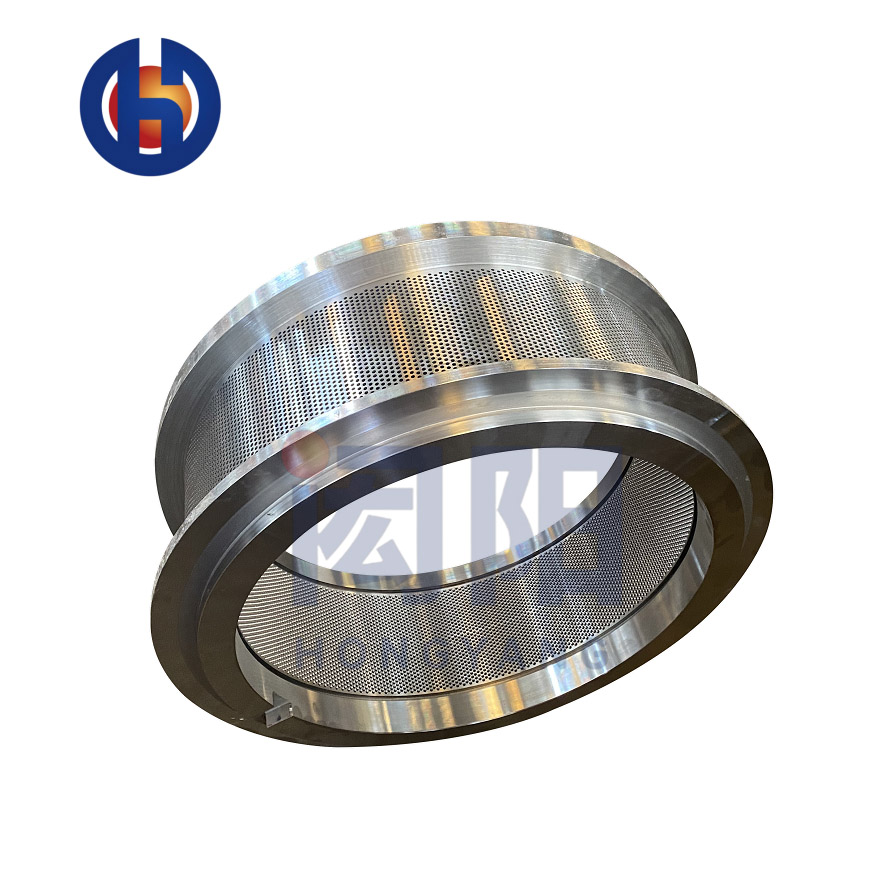

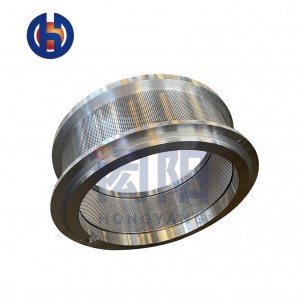

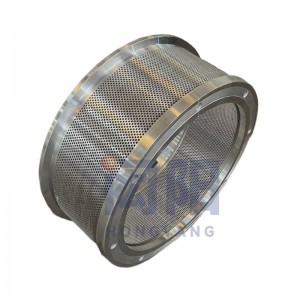

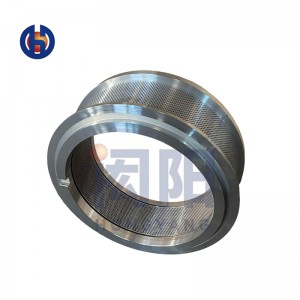

SZLH/ZHENGCHANG Ring Die For Pellet Machine

Technical Parameter

Diameter specification: Φ1.0mm and above

Material: high quality stainless steel, wear-resistant alloy steel

1. The ring die hole wear is small and the service life is long.

2. The particle shape is stable and the service life is long.

3.The dies adopts imported gun drill and multi-station group drill. The mold hole is formed at one time, with high smoothness, beautiful appearance of feed production, high output, smooth discharge and good particle formation.

|

Series |

Model |

|||||||||||

| SZLH | 250 | 300 | 320 | 350 | 350D | 400 | 400D | 420 | 420D | 428 | 508 | 508H |

| SZLH | 508E | 558E | 678 | 768 | 858 | 968 | 1068 | 1208 | 520X | 600X | 660X | 880X |

Selection of Ring Dies

Choosing the right ring die for your pellet mill is critical to achieving optimum performance and producing high-quality pellets. There are many factors to consider when selecting a ring die.

1. Types and specifications of raw materials

The type and size of the raw material you are processing will determine the size and style of the ring die holes. Some materials may require larger or smaller pores or different patterns to achieve the desired particle size and quality.

2. Particle size and quality

The size and quality of the pellets you produce will determine the design and quality of your ring die. A well-designed ring die will produce pellets of consistent size and quality, with a higher percentage of durable pellets.

3. Capacity of granulator

The capacity of the granulator is also an important factor to consider when choosing a ring die. A ring die with a larger diameter and more holes will produce more pellets per hour, while a smaller ring die will produce fewer pellets but may be better suited for smaller production runs or special applications.

4. Die material

The material of the ring die will greatly affect the service life and production quality of the pellet mill. There are generally two types of ring die materials: alloy steel and stainless steel. Stainless steel ring dies last longer and require less maintenance than alloy steel ring dies, but are more expensive.

5. Price

Price is always an important factor when choosing a ring die. While staying within the budget is important, it is equally important to choose a ring die that performs well and is durable.

Our Company