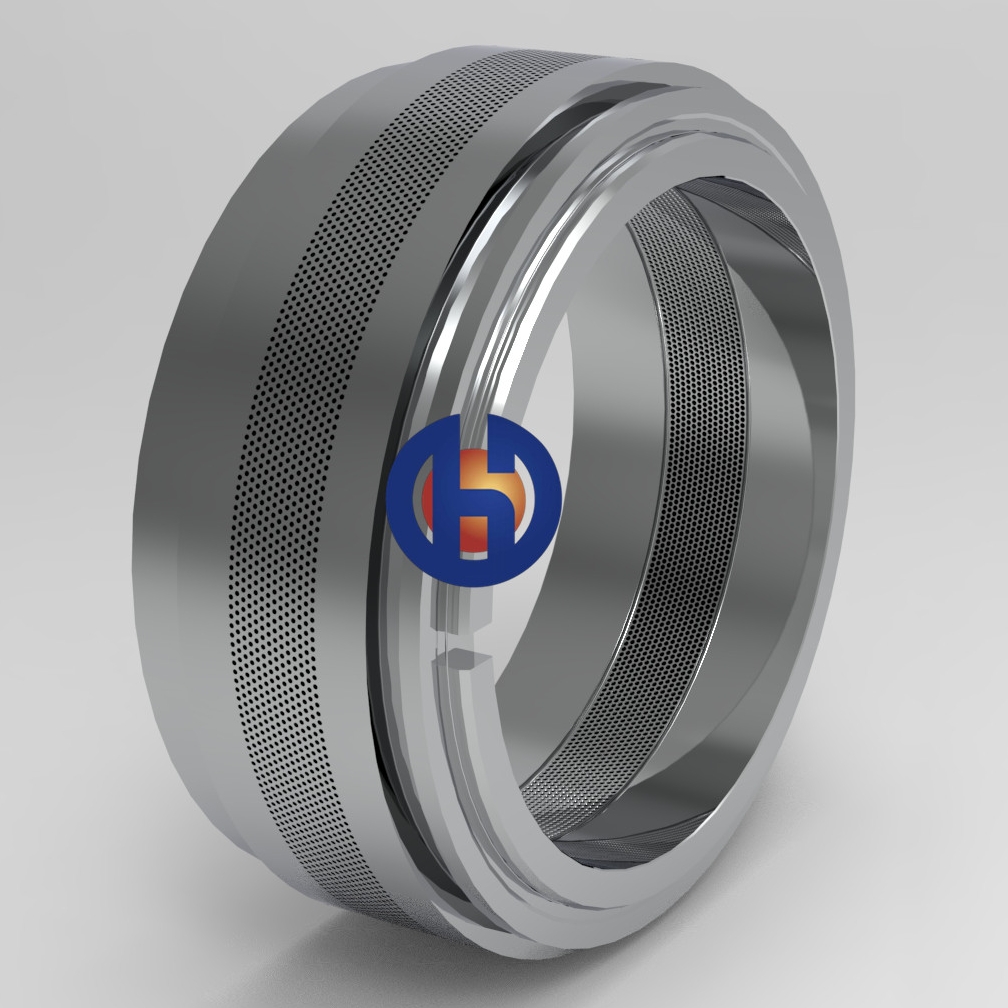

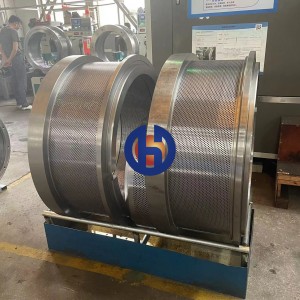

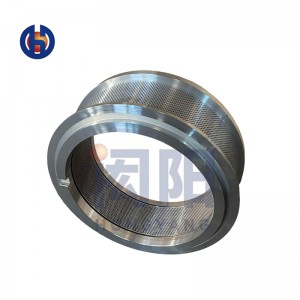

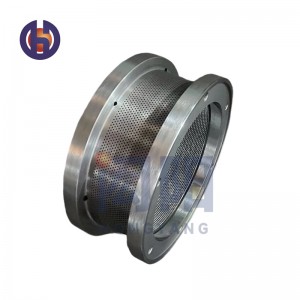

CPM Series Ring Die For Pellet Mill

Ring Die Materials and Heat Treatment

The ring die is usually made of carbon structural steel, structural alloy steel, and stainless steel through forging, cutting, drilling, heat treatment, and other processes. The materials used in the ring die and each processing procedure have a direct impact on its service life, granulation quality and output. Carbon structural steel mainly consists of 45 steel, whose heat treatment hardness is generally HRC45~50, and its wear resistance and corrosion resistance are poor, which are basically eliminated; The alloy steel mainly consists of 20CrMnTi material, which is subject to surface heat treatment such as surface carburization. The treatment hardness is above HRC50 and has good comprehensive mechanical properties. The ring mold made of this material has high strength and better wear resistance than 45 steel, but its disadvantage is poor corrosion resistance. Although the cost of a single ring mold is relatively low, the production cost of tons of material is higher than that of stainless steel ring mold when it is used, and it is now phased out; The stainless steel material is mainly 4Cr13. The rigidity and toughness of these materials are good. The heat treatment is overall firing, the hardness is greater than HRC50 and has good wear resistance and corrosion resistance. The service life is long, and the cost of per ton ring mold is low.

Composition of the 4Cr13 Material Ring Die

For the ring die of 4Cr13 material, its quality source must start from the ingot: the chemical composition (mass fraction%) of the ring die of 4Cr13 steel is: C content ≤ 0.36 ~ 0.45, Cr content 12 ~ 14, Si content ≤ 0.60, Mn content ≤ 0.80, S content ≤ 0.03, P content ≤ 0.035; In actual use, the service life of the ring die with about 12% Cr content is more than 1/3 shorter than that of the ring die with 14% Cr content under the same conditions of other treatments; So the source of ring die quality is from the steel lake. It is not only necessary to ensure that the Cr content is more than 13%, but also to ensure that the size and shape meet the requirements of forging.

CPM Series

|

S/N |

MODEL |

SizeOD*ID*overall width*pad width -mm |

|

1 |

CPM MASTER |

304*370*90*60 |

|

2 |

CPM 21 |

406*558*152*84 |

|

3 |

CPM16/25 |

406*558*182*116 |

|

4 |

CPM A25/212 |

406*559*212*116 |

|

5 |

CPM2016-4 |

406*559*189*116 |

|

6 |

CPM3000N/CPM3020-4 |

508*659*199*115 |

|

7 |

CPM3016-4 |

559*406*190*116 |

|

8 |

CPM3016-5 |

559*406*212*138 |

|

9 |

CPM3020-6/CPM3000W |

660*508*238*156 |

|

10 |

CPM3020-7 |

660*508*264*181 |

|

11 |

CPM3022-6/CPM7000/CPM7122-6/CPM7722-6 |

775*572*270*155 |

|

12 |

CPM3022-8 |

775*572*324.5*208 |

|

13 |

CPM7726-6 |

890*673*325*180 |

|

14 |

CPM7726-8 |

890*673*388*238 |

|

15 |

CPM7726-9SW |

890*672*382*239 |

|

16 |

CPM7932-9 |

1022.5*826.5*398*240 |

|

17 |

CPM7932-11 |

1027*825*455.5*275 |

|

18 |

CPM7932-12 |

1026.5*828.5*508*310.2 |

|

19 |

CPM7730-7 |

965*762*340*181 |

CPM 2016-4 CPM 3020-4 CPM 3020-6 CPM 3022-6 CPM 3022-8 CPM 7722-2 CPM 7722-4 CPM 7722-6 CPM 7722-7 CPM 7726-7 CPM 7730-4 CPM 7730-6 CPM 7730-7 CPM 7730-8 CPM 7930-4 CPM 7930-6 CPM 7930-8 CPM 7932-5 CPM 7932-7 CPM 7932-9 CPM 7932-11 CPM 7932-12 CPM 9636-7 CPM 7936-12 CPM 9042-12