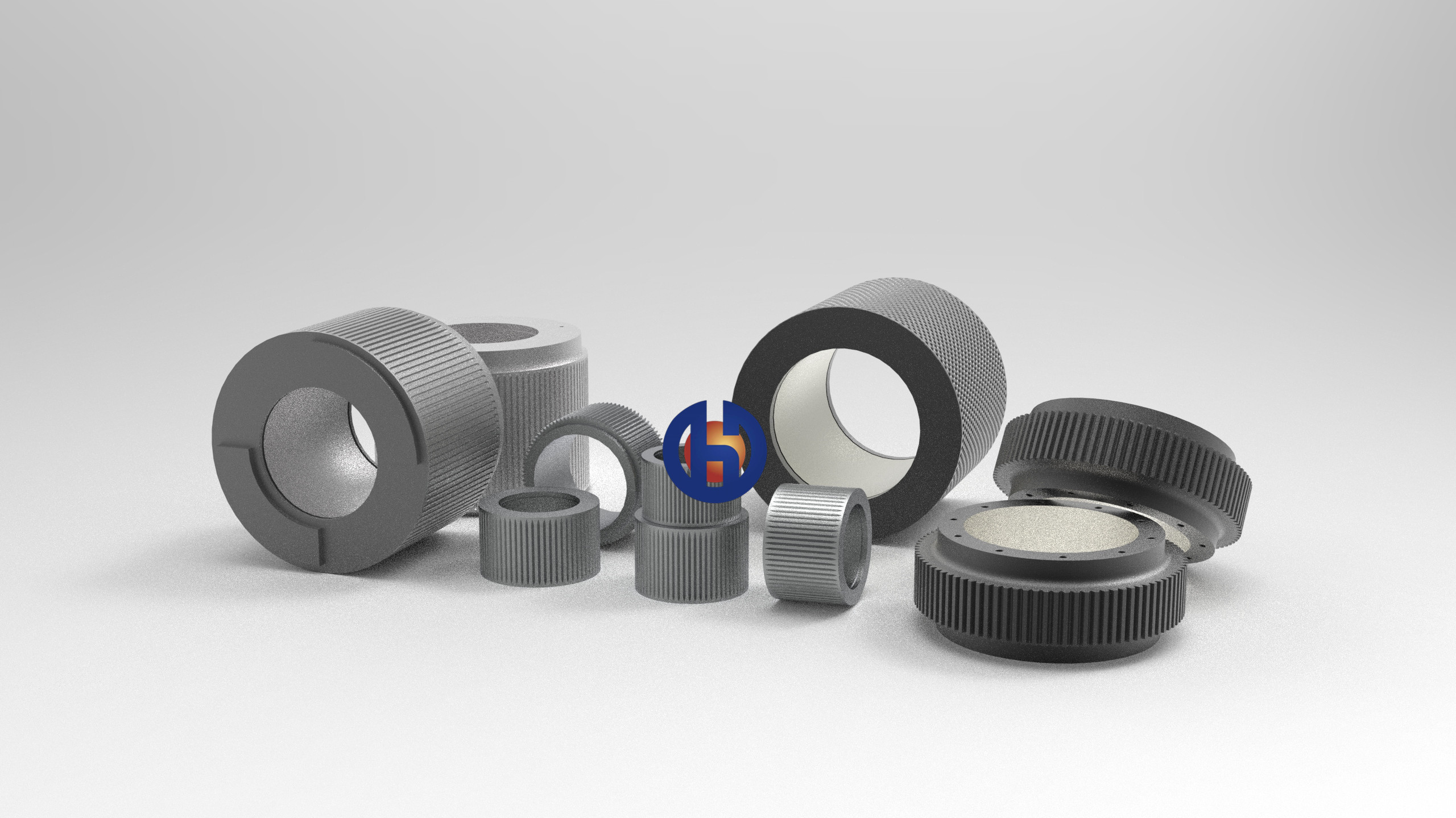

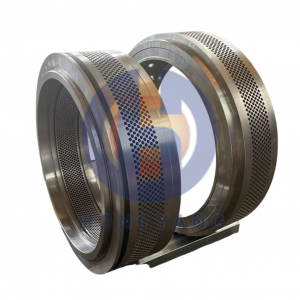

Roller Shell Mill Spare Parts For Pellet Machine

Fit of Pressing Roller and Ring Die

Before the installation of the press roll, the sundries in the assembly hole shall be carefully cleaned and greased. The large side of the left roll shall face up to the right, and the large side of the right roll shall face down to the left. The press plate shall be installed in the hole.

1. The roller die clearance is adjusted by turning the eccentric shaft anticlockwise to make the clearance smaller and clockwise to make it larger. The new ring die shall be equipped with a new press roll with a clearance of about 0.2mm and a normal production time clearance of 0.3mm. The adjustment of the roll die gap is very important. The gap is too small, the roll die directly contacts, the wear is increased, and the horn hole edge is damaged by rolling; If the clearance is too large, the output will be affected, and the machine is easy to be blocked, or even cannot be granulated. The experience shared by the old master is that when the ring die is turned by hand, it is better for the pressure roller to turn passively.

2. The axial fit of the press roll and the ring die mainly means that the axial position of the press roll and the working face of the ring die should be correct. Most of the press roll working faces are 4mm wider than the working face of the ring die. The most ideal fit is to evenly distribute 2mm in the front and back. The measuring method is to measure the distance between the end face of the ring die and the end face of the press roll with a vernier caliper that can measure the depth, and then calculate whether it is reasonable before making adjustments. If changes occur, they usually occur after the replacement of the main shaft bearing, or non-standard pressure rolls and accessories are used.