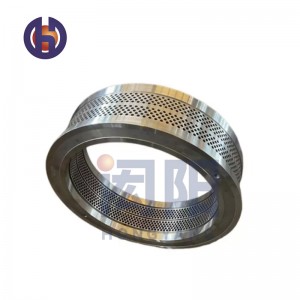

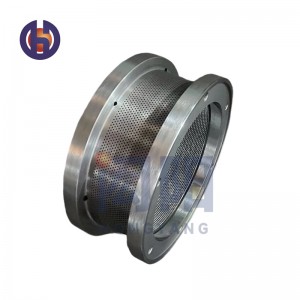

YULONG 560 XGJ560 Ring Die Feed Mill Parts

Correct Use of Ring Die

Polishing of new ring die

Before use, the new ring dies must be polished to remove any surface imperfections or rough spots that may have developed during the manufacturing process. The polishing process also helps to remove some iron chips and oxides that may be attached to the inner wall of the die holes so as to make it easier to release particles from the die holes, reducing the possibility of any clogging.

Polishing methods:

• Use the drill bit with diameter smaller than the diameter of ring die hole to clean the debris blocked in the ring die hole.

• Install the ring die, wipe a layer of grease on the feed surface, and adjust the spacing between the rollers and the ring die.

• Use 10% of fine sand, 10% of soybean meal powder, 70% of rice bran mixed, and then mixed with 10% of grease abrasive, start the machine into the abrasive, processing 20 ~ 40min, with the increase of die hole finish, the particles gradually loose.

Remember this important first step in preparing the ring die for pellet production, helping to ensure consistent pellet size and quality produced.

Adjusting the working gap between the ring die and the pressure roller

The working gap between the ring die and the press rolls in a pellet mill is a key factor for pellet production.

Generally speaking, the gap between the ring die and the pressure roller is between 0.1 and 0.3mm. If the gap is too large, the friction between the ring die and the pressure roller is not enough to overcome the friction of the material through the die hole and cause the machine to plug. If the gap is too small, it is easy to damage the ring die and pressure roller.

Usually, the new pressure roller and the new ring die should be matched with a slightly larger gap, the old pressure roller and the old ring die should be matched with a smaller gap, the ring die with a large aperture should be selected with a slightly larger gap, the ring die with small aperture should be selected with a slightly smaller gap, the material that is easy to granulate should take a large gap, the material that is difficult to granulate should take a small gap.

Cautions

1. During the use of the ring die, it is necessary to avoid mixing sand, iron blocks, bolts, iron filings and other hard particles into the material, so as not to accelerate the wear of the ring die or cause excessive impact on the ring die. If iron filings enter the die hole, they must be punched out or drilled out in time.

2. Whenever the ring die is stopped, the die holes should be filled with non-corrosive, oily raw material, otherwise the residue in the cold ring die holes will harden and cause the holes to become blocked or even corroded. Filling with oil-based material not only prevents the holes from being blocked, but also washes away any fatty and acidic residues from the hole walls.

3. After the ring die has been used for a period of time, it is necessary to regularly check whether the die hole is blocked by materials and clean it in time.