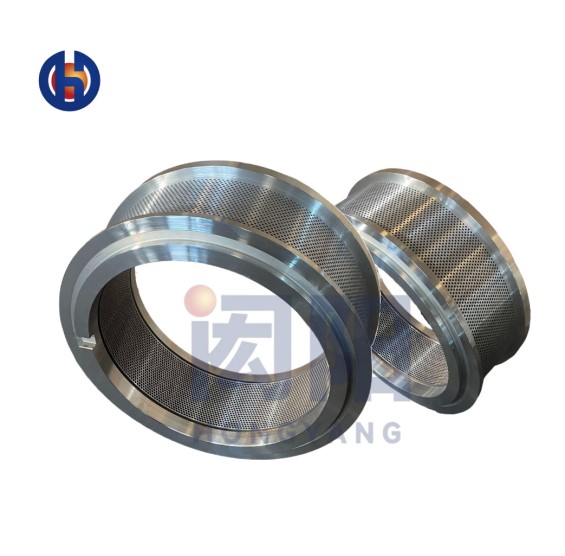

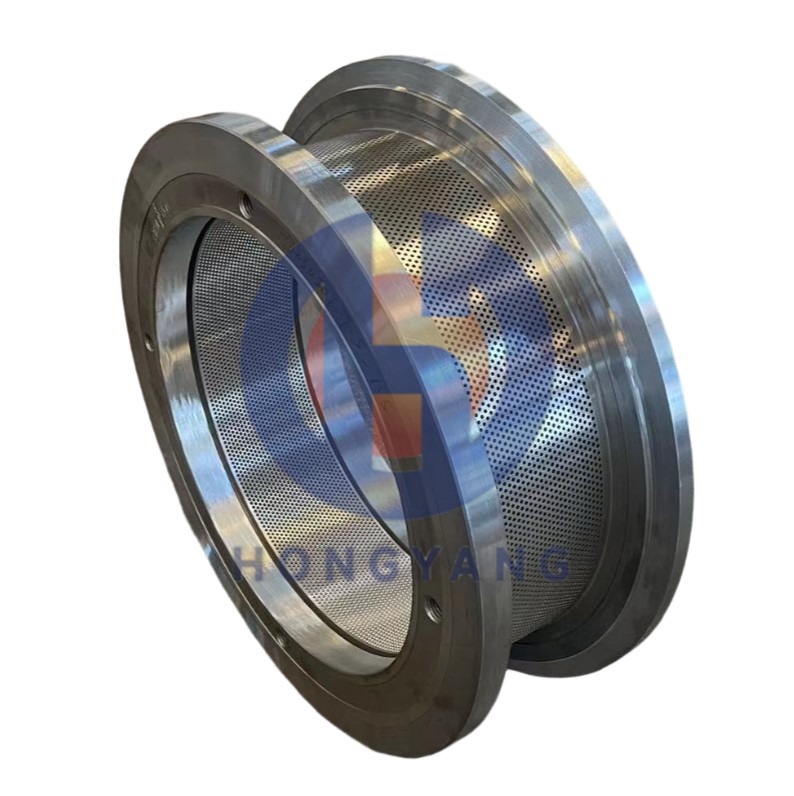

The ring die is the main vulnerable part of the pellet mill, and the quality of the ring die directly affects production efficiency and finished product quality. In the production process, the crushed feed is tempered and enters the granulation equipment. Under the compression of the ring die and pressure roller, it is extruded from the hole die and then cut into the required particle length by a cutting knife.

Factors that determine the quality of the ring die

1. Wear resistance: The main consumption of the ring die comes from wear. Due to prolonged squeezing, the ring die hole increases and the surface wears. The wear resistance of the ring die depends on its hardness and material composition. To achieve the best wear resistance, scientific heat treatment methods need to be used, and the selection of materials is also crucial.

2. Corrosion resistance: Because some feed ingredients and additives become more corrosive under high temperature and heat, they constantly corrode the die. So corrosion resistance is the most important factor and must be controlled. High chromium and high carbon are the best choices.

3. Toughness: During the granulation process, the ring die bears a lot of pressure, causing immediate damage to the ring die. The number of die holes, heat treatment process, and material selection are all factors that affect toughness.

At present, the quality of ring dies in the market varies, mainly due to differences in material selection, process selection, and processing technology. The ring dies produced by some small factories are forged from carbon steel or alloy and then subjected to ordinary heat treatment. This type of ring die is prone to various problems such as high energy consumption, low production capacity, and die explosion during production; The more serious harm is that the non wear-resistant and low lifespan of the ring die will greatly affect the feed formula and affect the granulation quality.

It is recommended to choose the ring die produced by Hongyang Feed Machinery, which has advanced technology and reasonable material selection; Choosing stainless steel forging embryos is a guarantee of long service life; Hongyang Feed Machinery uses a drilling machine to process ring dies, with smooth and flat die holes and good discharge quality; The selection of vacuum heat treatment technology for ring dies further ensures corrosion resistance and wear resistance.

Technical Support Contact Information:Bruce

TEL/Whatsapp/Wechat/Line : +86 18912316448

E-mail:hongyangringdie@outlook.com

Post time: Oct-09-2023