Is the molding effect of biomass pellets not good? Here comes the cause analysis!

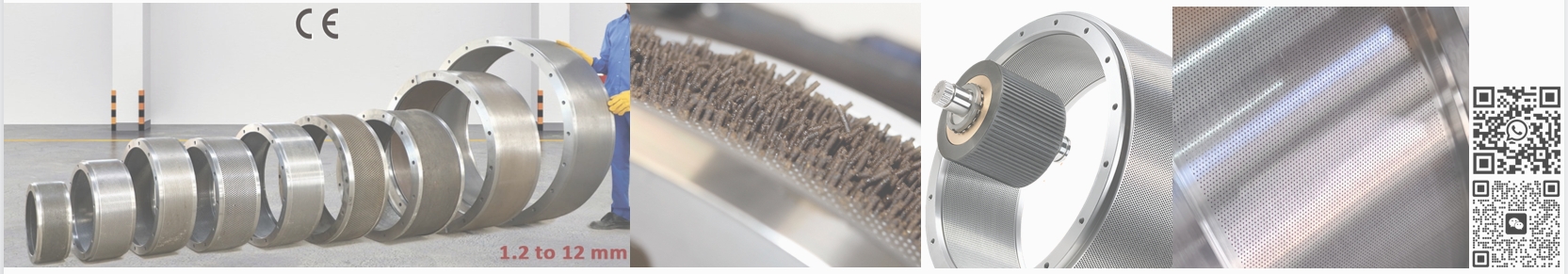

Biomass ring die granulation equipment can solidify and extrude logs, sawdust, shavings, corn and wheat straw, straw, construction templates, woodworking scraps, fruit shells, fruit residue, palm, and sludge sawdust into high-density granular fuel through pre-treatment and processing.

If the pellet formed during the processing are loose or not formed, many users will first think that there is a problem with the machine. Of course, first we need to check whether all parts of the machine are normal and find the root cause through debugging. If the device is functioning properly, then it is due to other reasons. Our Hongyang Feed Machinery have specifically summarized three common types.

1、 Problems with the raw materials themselves

The characteristics of different raw materials are different, the fiber structure is also different, and the difficulty of forming is also different. For example, palm is a relatively difficult to press material, while wood chips have their own bonding effect at a high temperature of 80 degrees Celsius, so no adhesive is required. In addition, if it is a mixed material, the mixing ratio of each material will also affect the forming rate.

2、 Moisture content of raw materials

When making biomass pellets, the moisture content of the raw material is an important indicator. If the moisture content is too high, the pellet made will be very soft and difficult to form. Therefore, it is necessary to use a drying process to achieve normal granulation of the pelletmachine. The water content is generally around 15%, and Liangyou will conduct targeted process design for customer raw materials and provide professional solutions.

3、 pellet size of raw materials

The pellet size of raw materials is also an important factor affecting the granulation process. Usually, the crushing pelletsize is around 3-4mm and cannot exceed 5mm. The smaller the crushing pelletsize, the easier it is to form, but even if it is too small, it will not work, and there will be a situation where the powder content is too high. If the pelletsize is too large, it will lead to the inability of the granulation equipment to operate normally and effectively, resulting in problems such as high energy consumption, low output, uneven granulation, and surface cracks on the finished product pellet, greatly affecting production efficiency.

Hongyang Feed Machinery’s biomass granulation equipment can be designed specifically for customers to meet the granulation needs of various types of raw materials. The finished product is beautiful and the pellet are uniform, improving market competitiveness for customers.

Technical Support Contact Information:Bruce

TEL/Whatsapp/Wechat/Line : +86 18912316448

E-mail:hongyangringdie@outlook.com

Post time: Sep-25-2023