1. The pellet material is bent and exhibits many cracks on one side

This phenomenon generally occurs when the particles leave the ring die. When the cutting position is adjusted far from the surface of the ring die and the blade is blunt, the particles are broken or torn by the cutting tool when squeezed out of the die hole, rather than being cut off. At this time, some particles bend towards one side and the other side presents many cracks.

Improvement methods:

• Increase the compression force of the ring die on the feed, that is, increase the compression ratio of the ring die, thereby increasing the density and hardness value of the pellet material;

• Crush the feed material to a finer size. As long as molasses or fats are added, the distribution uniformity of molasses or fats should be improved and the amount added should be controlled to increase the compactness of the pellet material and prevent the feed from becoming soft;

• Adjust the distance between the cutting blade and the surface of the ring die or replace it with a sharper cutting blade;

• Adopting adhesive type granulation additives to improve the bonding force between particles.

2. Horizontal cracks cross the entire particle material

Similar to the phenomenon in scenario 1, cracks occur at the cross-section of the particles, but the particles do not bend. This situation may occur when pelletizing fluffy feed containing a large amount of fiber. Due to the presence of fibers longer than the pore size, when the particles are extruded, the expansion of the fibers causes transverse cracks in the cross-section of the particle material, resulting in a fir bark like feed appearance.

Ways to improve:

• Increase the compression force of the ring die on the feed, that is, increase the compression ratio of the ring die;

• Control the fineness of fiber crushing, ensuring that the maximum length does not exceed one-third of the particle size;

• Increase production to reduce the speed of feed passing through the die hole and increase compactness;

• Extend the tempering time by using multi-layer or kettle type conditioners;

• When the moisture content of the powder is too high or contains urea, it is also possible to produce a fir bark like feed appearance. The added moisture and urea content should be controlled.

3. Vertical cracks occur in pellet materials

The feed formula contains fluffy and slightly elastic procurement, which will absorb water and expand when adjusted by the conditioner. After being compressed and granulated by the ring die, it will spring apart due to the effect of water and the elasticity of the raw material itself, resulting in vertical cracks.

The ways to improve are:

• Change the formula, but doing so may reduce the cost of raw materials;

• Use relatively saturated dry steam;

• Reduce production capacity or increase the effective length of the die hole to maximize the retention time of feed in the die hole;

• Adding adhesive can also help reduce the occurrence of vertical cracks.

4. Radiative cracking of pellet materials from a single source point

This appearance indicates that the pellet material contains large pellet raw materials, which are difficult to fully absorb the moisture and heat in the water vapor during quenching and tempering, and are not as easily softened as other finer raw materials. However, during cooling, different softening levels cause differences in shrinkage, leading to the formation of radial cracks and an increase in pulverization rate.

The ways to improve are:

Control and improve the fineness and uniformity of raw materials, so that all raw materials need to be fully and uniformly softened during tempering.

5. The surface of the pellet material is uneven

The above phenomenon is that the powder is rich in large particle raw materials, which cannot be fully softened during the tempering process. When passing through the die hole of the granulator, it cannot be well combined with other raw materials, making the particles appear uneven. Another possibility is that the quenched and tempered raw material is mixed with steam bubbles, which generate air bubbles during the process of pressing the feed into particles. At the moment when the particles are squeezed out of the ring die, changes in pressure cause the bubbles to break and cause unevenness on the surface of the particles. Any feed containing fiber may experience this situation.

Improvement methods:

Properly control the fineness of powdered feed, so that all raw materials can be fully softened during conditioning; For raw materials with a considerable amount of fiber, as they are prone to steam bubbles, do not add too much steam to this formula.

6. Beard like pellet material

If too much steam is added, the excess steam will be stored in fibers or powder. When the particles are extruded from the ring die, the rapid change in pressure will cause the particles to burst and protrude from the surface of the protein or particle raw materials, forming prickly whiskers. Especially in the production of high starch and high fiber content feed, the more steam is used, the more serious the situation.

The improvement method lies in good tempering.

• Feed with high starch and fiber content should use low-pressure steam (0.1-0.2Mpa) to fully release water and heat in the steam for feed absorption;

• If the steam pressure is too high or the downstream pipeline behind the pressure reducing valve is too short from the regulator, which should generally be greater than 4.5m, the steam will not release its moisture and heat very well. Therefore, some steam is stored in the feed raw materials after conditioning, which can cause the whisker like particle effect mentioned above during granulation. In short, special attention should be paid to the pressure regulation of the steam and the installation position of the pressure reducing valve must be correct.

7. Individual particles or particles with inconsistent colors between individuals, commonly known as "flower materials"

It is common in the production of aquatic feed, mainly characterized by the color of individual particles extruded from the ring die being darker or lighter than other normal particles, or the surface color of individual particles being inconsistent, thereby affecting the appearance quality of the entire batch of feed.

• The raw materials for aquatic feed are complex in composition, with multiple types of raw materials, and some components are added in relatively small amounts, resulting in unsatisfactory mixing effects;

• Inconsistent moisture content of raw materials used for granulation or uneven mixing when adding water to the mixer;

• Recycled material with repeated granulation;

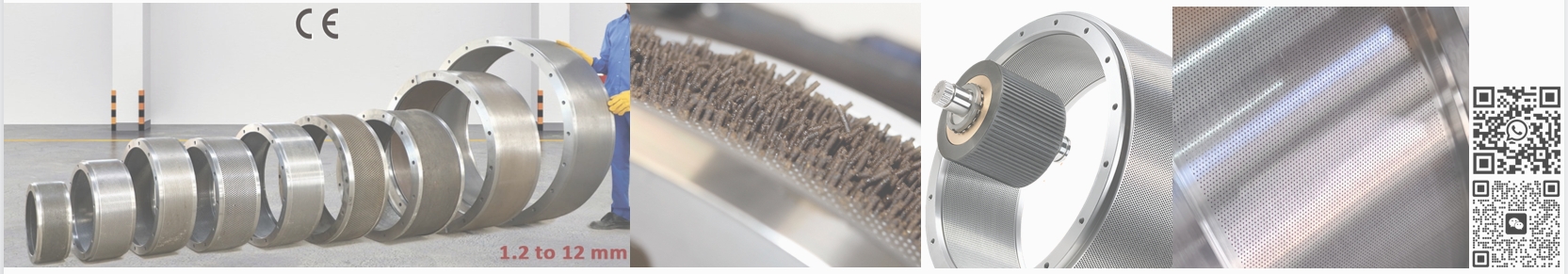

• Inconsistent surface finish of the inner wall of the ring die aperture;

• Excessive wear of the ring die or pressure roller, inconsistent discharge between small holes.

Technical Support Contact Information:

Whatsapp: +8618912316448

E-mail:hongyangringdie@outlook.com

Post time: Aug-18-2023