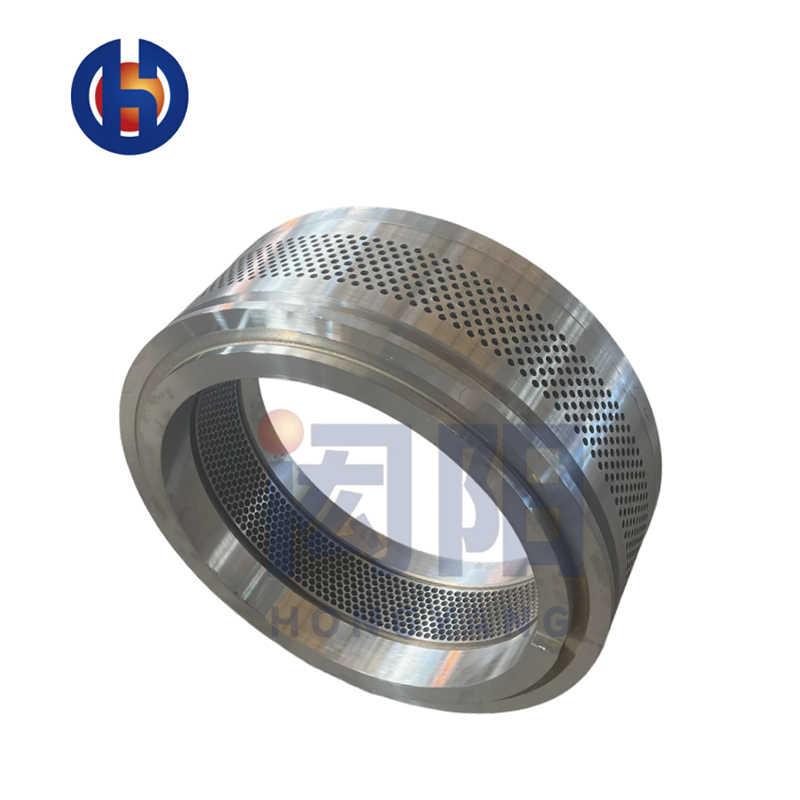

MZLH/ZHENGCHANG Ring Die Pellet Press Die

Technical Parameter

Diameter specification: Φ6.0mm and above

Material: high quality stainless steel (X46Cr13、4Cr13), wear-resistant alloy steel

The die adopts the treatment process combining the vacuum furnace and continuous quenching furnace of the United States, with uniform quenching, good surface finish and high hardness, ensuring twice the service life

Specification parameters of biomass pellet mill ring die:

Material: high-quality high-chromium manganese steel

Processing aperture: 6.00mm – 16.00mm

Outer diameter of processed workpiece: 500mm-1100mm

Inner diameter of processed workpiece: 400mm-900mm

Surface hardness: HRC 58-62

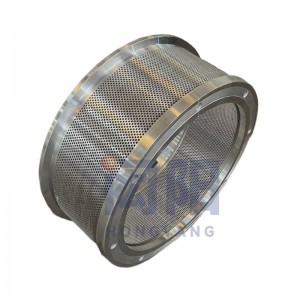

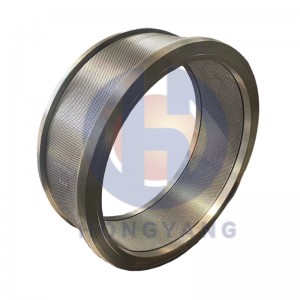

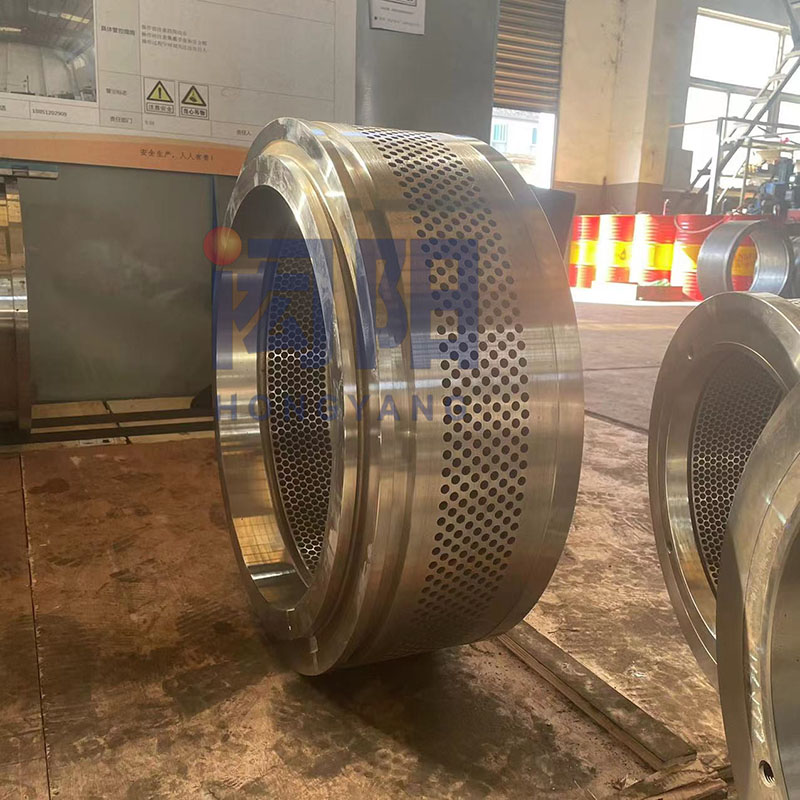

Product Display

Product Maintenance

The ring die is the key part of the pellet mill, responsible for shaping the raw material into pellets. Maintaining and properly servicing the ring die is very important to ensure the optimal functioning of the pellet mill and to ensure that the pellets produced are of good quality. Here are some tips to help you maintain your pellet mill ring die:

1. Keep the ring die clean

One of the most important things you can do with your ring die is to keep it clean. Remove any built-up material or debris from the mold and make sure it doesn't have any cracks or damage. You can clean the mold by running a soft brush through the holes and scraping away any built-up residue.

2. Regular oiling

The next maintenance step is to periodically lubricate the ring die. This will help prevent friction, which can deform the die and damage the pelletizer. Use a good quality lubricant that is compatible with the ring die material.

3. Adjust the gap between the ring die and the pressure roller

Another important factor in the maintenance of the ring die is to adjust the gap between the ring die and the pressure roller. Proper clearance ensures that the feedstock is properly compressed, resulting in high-quality pellets. The clearance should be adjusted according to the type of material being processed and the desired particle size.

4. Replace the mold if necessary

Over time, ring dies can wear and deform, which can lead to poor pellet quality and even damage to the pellet mill itself. It is important to replace ring dies when necessary to maintain optimum performance. Replace the ring die with one made specifically for your pellet mill to ensure proper fit.