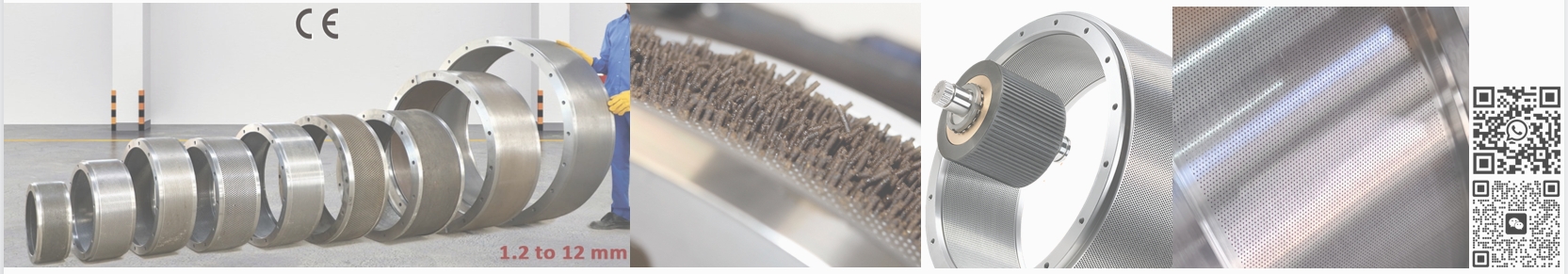

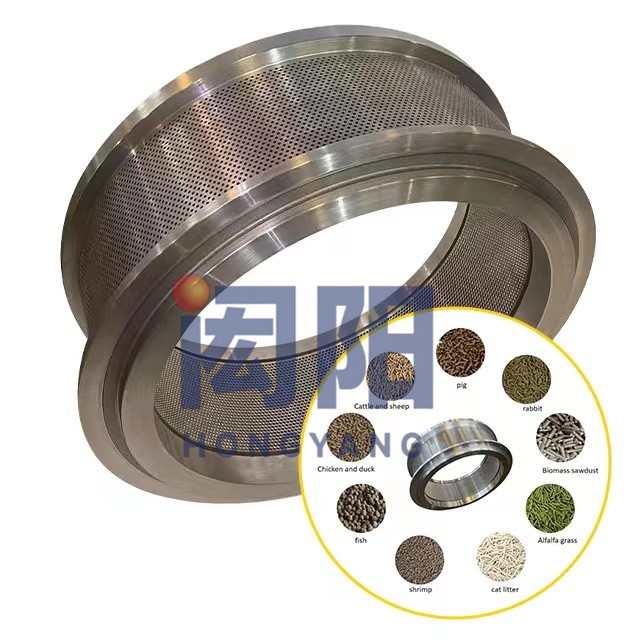

The ring die is an important part of the feed granulator/pellet mill, and its performance largely determines the feed processing output, playing a very important role in the feed processing process. However, some customers have reported that during the production process, the ring die may burst.

The following reasons were summarized through experiments:

1. The material performance used in the ring die is unstable and uneven;

2. If the opening rate of the ring die is too high, the strength and toughness of the ring die itself will decrease;

3. The thickness of the ring die is too thin, and the strength of the ring die decreases;

4. The ring die is forcibly squeezed by hard objects during operation;

5. The eccentric state or uneven tightening of the ring die during installation (concentric with the pressure roller assembly, etc.) causes the ring die to continuously withstand unidirectional impact.

Thicker mold/ring die to improve the quality of particles, because of the increased feed pellets and the friction between the die wall, also raised the rate of starch gelatinization. However, using thicker or aperture thin mold can reduce productivity. In addition, the distance between rollers and the mould increased from 0.1 mm to 2 mm, can improve the durability of the particles.

As a customer of our Hongyang Feed Machinery Company, we provide customers with higher quality ring dies,more durable, and has higher production capacity. We recommend and customize the most suitable compression ratio and aperture for customers.

Technical Support Contact Information:

TEL/Whatsapp : +86 18912316448

E-mail:hongyangringdie@outlook.com

Post time: Sep-11-2023