The ring die of feed machine accessories is a widely used mechanical part, which is conducive to improving the efficiency of animal feeding. Its sales are all over the world, 88% of which are from China, which shows that it has been widely recognized.

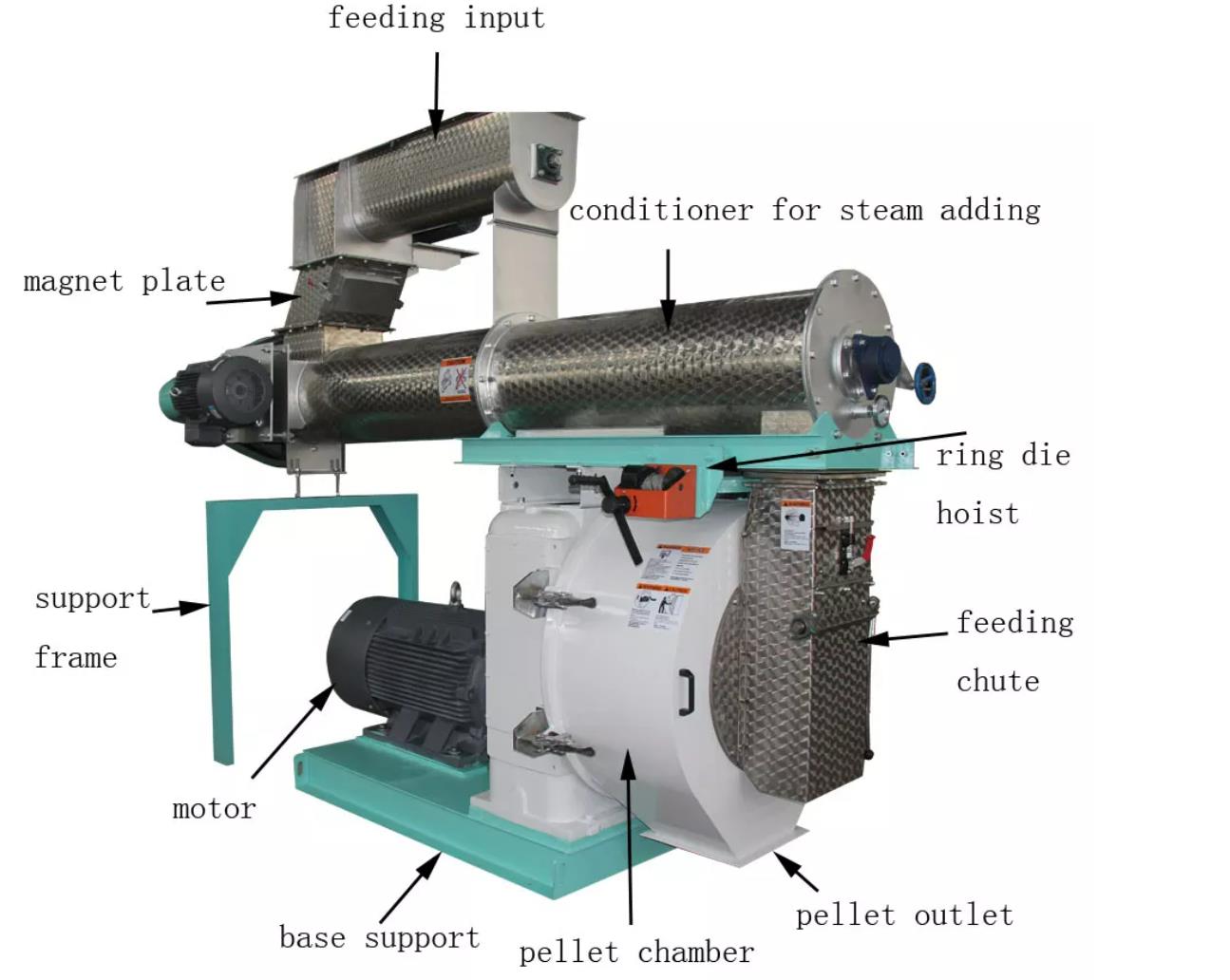

The ring die for feed machine accessories is mainly used in the production of feed machine and is an important part of the automatic feed processing machine. It can make the feed machine run more smoothly, improve the output of the feed machine, thus reducing the cost of animal feeding, and faster production efficiency can also meet certain market demands.

In addition, the ring mold is usually made of high-quality materials, and its surface has special surface treatment, such as heat treatment, galvanizing treatment, etc., which has the advantages of high strength, corrosion resistance, wear resistance, heat resistance, etc., which can ensure stable and reliable production performance of feed machine and prolong its service life.

In addition, the ring mold of feed machine accessories can also be customized according to the customer’s requirements. If there are special customer needs, it can also be met. Therefore, it has broad application prospects.

In short, the sales volume of the ring die for feed machine accessories is all over the world, of which 88% are from China, which is widely recognized. It has the advantages of high strength, corrosion resistance, wear resistance, etc. It can be customized according to customers’ requirements. It has a broad future development prospects and will play an important role in animal breeding and mechanical processing industry.

Ring mold compression ratio refers to the compression of raw materials to a fixed limit to obtain a specific compression ratio, which is used to measure the maximum compression that the compressor can withstand. The determination of the ring mold compression ratio is mainly based on the type of compressor, the shape of the compression chamber, the nature of raw materials and particle size, and other factors to determine the best compression ratio.

First, the compression ratio should be determined according to the type of compressor. Different types of compressors have different compression ratios. Second, the compression ratio should be determined according to the shape of the compression chamber. Different shapes of compression chambers have different compression ratios. Third, the compression ratio should be determined according to the nature of raw materials, such as the hardness and dispersion of raw materials; Finally, the compression ratio should be determined according to the particle size. Generally, the compression ratio of raw materials with larger particles is lower, while the compression ratio of raw materials with smaller particles is higher.

To sum up, the determination of the compression ratio of the ring mold should be considered according to the type of compressor, the shape of the compression chamber, the nature of raw materials and the particle size, so as to achieve the best compression ratio for different raw materials.

Post time: Mar-14-2023