1. Feed expansion material: Feed expansion material refers to the rapid expansion of feed raw materials under high temperature, high pressure, and humid heat conditions, forming porous expansion particles. The technological advantages of feed puffing materials include:

-Improving feed utilization: The puffing process can significantly improve feed utilization. Expanding can change the physical properties of feed materials, make protein more digestible and absorbed, and increase Mashing rate, which is helpful to improve feed conversion efficiency and growth speed of animals.

-Sterilization and pest control: The effects of high temperature and pressure during the puffing process can effectively kill bacteria and viruses in feed, reduce the risk of animal infection, and improve the health level of animals.

-Improving the taste of feed: Expanding can improve the taste of feed, increase appetite, promote normal animal eating, and reduce feed waste.

2. Feed pellet: Feed pellet is a granular material made from feed to a certain size and shape. The technological advantages of feed pellets include:

-Improving the stability of feed: Granular feed helps to evenly mix and stabilize feed ingredients, reducing the layering and deposition of various components in the feed, improving feed stability, and ensuring that animals receive balanced nutrition.

-Convenient storage and transportation: Granular materials are easy to store and transport, and are not susceptible to moisture, mold, and oxidation. The regular shape and solid properties of granular materials make storage space more efficient, facilitate storage and transportation, and reduce feed loss and waste.

-Adapt to different animal needs: Granular materials can be prepared into particles of different sizes and shapes, which can be adjusted according to the oral structure and digestive characteristics of different animals, providing feed suitable for chewing and digestion of different animals.

In summary, the process of choosing between extruded feed or pellet feed depends on the specific situation. If you pursue advantages in improving feed utilization, sterilization and pest control, and improving taste, you can choose feed puffing materials; If you pursue the advantages of feed stability, convenient storage and transportation, and adaptability to different animal needs, you can choose feed pellets. At the same time, different feed processing methods can also be comprehensively considered based on factors such as animal species, growth stages, and feeding methods.

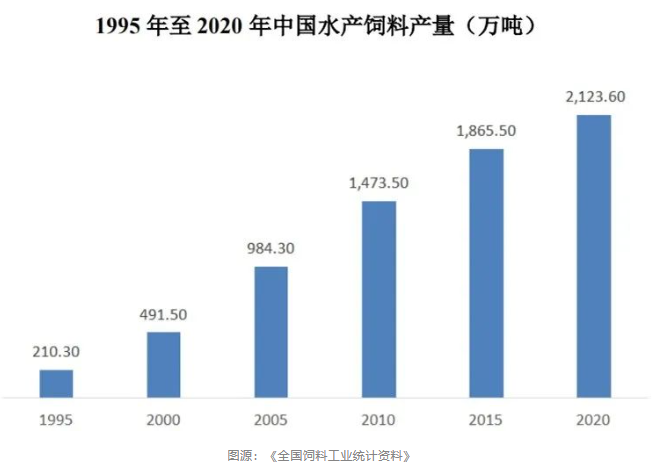

In 2020, the production of aquatic feed in China reached 21.236 million tons. From 1995 to 2020, aquatic feed maintained rapid growth in the feed industry and is expected to have a stable and huge market space in the future.

Expanded feed, also known as clinker, is processed through the puffing process. The expansion of feed raw materials alters their appearance, structure, and even organic matter, making them more conducive to digestion and absorption by animals.

The production process of puffed feed and pellet feed mainly differs in several stages such as conditioning, puffing, and liquid spraying:

1. Tempering: After tempering, the moisture content of the puffed material is about 25%, while that of the granular material is about 17%. And when adjusting the quality of puffed materials, water and steam are added together, while for granular materials, only steam is added.

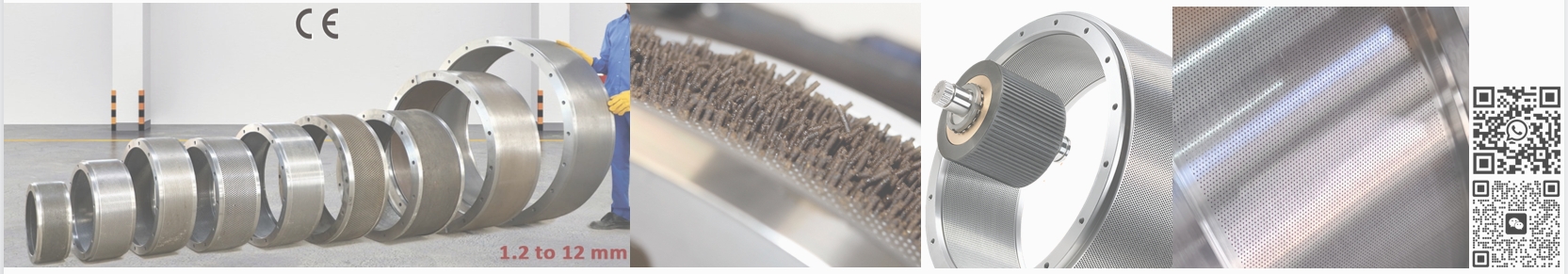

2. Expansion and spraying: The expansion material is mainly produced in the expansion and spraying section, using specialized expansion machines and oil spraying equipment. After spraying, the feed has a good appearance, strong palatability, and strong nutritional value. The granular material does not have these two processes, but there is an additional granulation process.

Expanded feed adopts ultra-fine crushing, which has a finer particle size compared to granular materials and is easier to absorb. However, due to high temperature and pressure, protein damage can occur. The processing temperature of the granular material is around 80 degrees Celsius, and there is basically no loss of nutritional components, but the bacteria, fungi, etc. in it cannot be completely killed. Therefore, compared to ordinary granular materials, puffed materials are safer and reduce the risk of animal disease.

Post time: Jun-29-2023