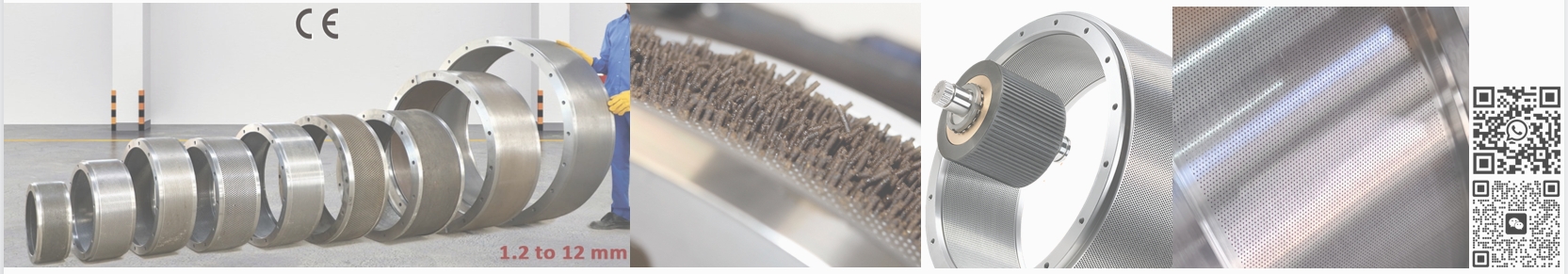

The gap adjustment between the pressure roller and the ring mold of the granulator is an important part of operating the granulator. If the gap adjustment is reasonable, the granulator will have high output, low energy consumption, good particle quality, low wear of the pressure roller and ring mold, and long service life.

The granulator cannot work properly, the particle quality is not guaranteed, and if the gap between the pressure roller and the ring mold is too small, it will wear severely, and even cause the ring mold to burst. This puts forward high requirements for granulator operators, who need to have rich knowledge of pressure roller adjustment. In order to reduce the impact of unstable factors caused by human operations, and also to reduce human work intensity and improve production efficiency.

The automatic adjustment technology for the gap between the pressure roller and the ring mold has emerged.

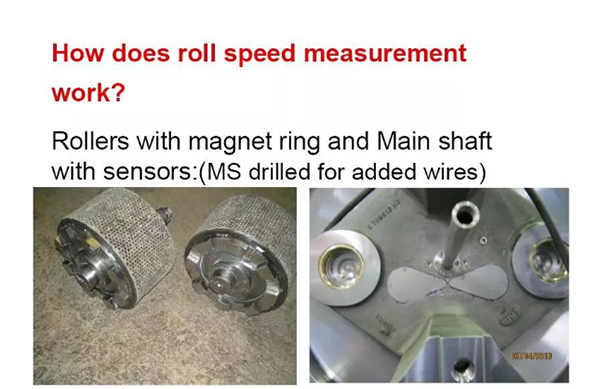

Technical principles:

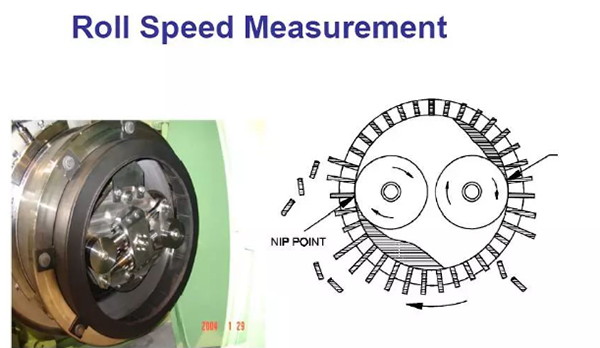

The system is mainly composed of an oil cylinder execution system, an angle sensor, and a PLC control system. The function of the oil cylinder execution system is to push the pressure roller to rotate clockwise or counterclockwise, even if the gap between the pressure roller and the ring mold increases or decreases;

The function of the angle sensor is to sense the changes in the angle of the pressure roller and transmit the change signal to the PLC control system; The PLC control system is responsible for converting the change in the angle of the pressure roller into the change in the size of the gap between the pressure roller and the ring mold, and comparing it with the set gap value to determine the direction and size of the oil cylinder execution system until the actual gap and the set gap are consistent within the allowable range of error.

Technical advantages:

The on-site touch screen serves as the interactive interface, making it easy to operate;

Reduce metal to metal contact, reduce wear on the pressure roller and ring mold, greatly extending the service life;

Reduce electrical demand, reduce downtime, and save time and costs;

High adjustment accuracy, the gap error between the pressure roller and the ring mold can be controlled within ± 0.1mm;

It can be adjusted at any time during the operation of the granulator, greatly improving work reliability and efficiency, and reducing labor intensity;

No lubricating oil, increasing feed safety.

Post time: Jul-12-2023